BOXLINEIntelligent equipment

Gain a competitive advantage in the industry through intelligent production

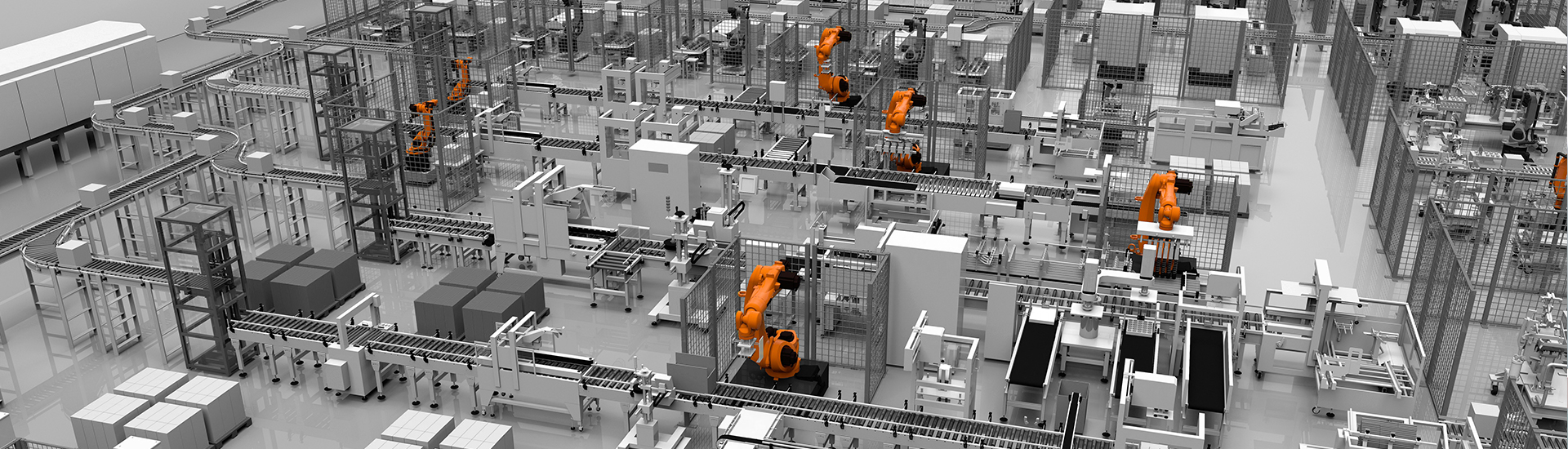

Intelligent factory automation overall solution Intelligent storage, transportation, intelligent packaging, and factory intelligent software integration are the core links of the FA system (Factory Automation). It is the current industry to maximize production capacity and optimize the use of factory production and storage air news Development trend. Today's market needs are diverse, labor costs are increasing, logistics production efficiency is generally low, and end customers and enterprises are demanding more intelligent, personalized, and customized services, which place high demands on the flexible automation and intelligence levels of factories.

BOXLINENot only provide you with intelligent warehousing, automatic logistics, intelligent packaging, industrial robot applications and software service products, but also provide customers with personalized and customized overall factory intelligence solutions through their extensive industry knowledge, helping you build a complete factory intelligence Production, logistics, warehousing and software control systems.

BOXLINEIntelligent equipment

FA system

Has a national outstanding technical design team, annual sales of more than 400 robot production lines, leading more than 200 smart factory design. With strong innovation capabilities and solution competitiveness, Bokelai becomes an outstanding representative of China's factory automation industry.

Working with KUKA

Deep cooperation with KUKA

As early as 2005, Bokola began cooperation with KUKA at different levels, and is currently the highest-level authorized agent in the northern region of KUKA Robotics. KUKA is a leading global supplier of industrial robots and equipment and systems technology, and a pioneer in Industry 4.0. KUKA possesses excellent genes made in Germany. His stable and efficient robotic equipment has opened up a vast world for intelligent manufacturing.

Service manufacturing

Provide full-cycle product services

From pre-planning to post-debugging, from maintenance to retrofit, Bokolite full service provides customers with complete service products throughout the entire life cycle of the system.

For safety and production efficiency, we provide systematic and comprehensive training to share our rich experience and knowledge accumulated in thousands of projects with customers.

As a benchmark for the quality of provincial industrial enterprises, Bokele provides excellent industry guarantees for quality and quality.